Progress in semiconductor devices architecture, such as three-dimensional device packaging, poses serious challenges for failure analysis due to overlapping structures and fields. Engineers need to localize and understand electrical failure in elements with complex shapes and multiple origins of contrast. It becomes tricky to correctly distinguish signals from Electron Beam Induced Current (EBIC) and Electron Beam Absorbed Current (EBAC), or between Resistive Contrast Imaging (RCI) and Electron Beam Induced Resistance Change (EBIRCH).

As a consequence, Electrical Failure Analysis (EFA) trends became contradictory. More complex data has to be collected, but at the same time, there is a need for more intuitive data visualization and interpretation. New dedicated electronics by point electronic GmbH that were added to our integrated EFA solution include multiple independent channels and advanced software for color coding.

In this application note, we show how color-coded EFA signal acquisition can significantly simplify EFA workflow on complex structures. We show color-coded EBIC and EBAC on various size transistors, including 7nm technology nodes. We also show how image math can be used to distinguish between different origins of contrast and to analyze only the signal we are interested in.

EBIC / EBAC techniques for semiconductor failure analysis

Transistor characterization of a 5nm SRAM die

Failure mechanism investigation of single bits in flash memory array

EBIC measurement of the minority carriers’ diffusion length in a GaAs solar cell p-n junction

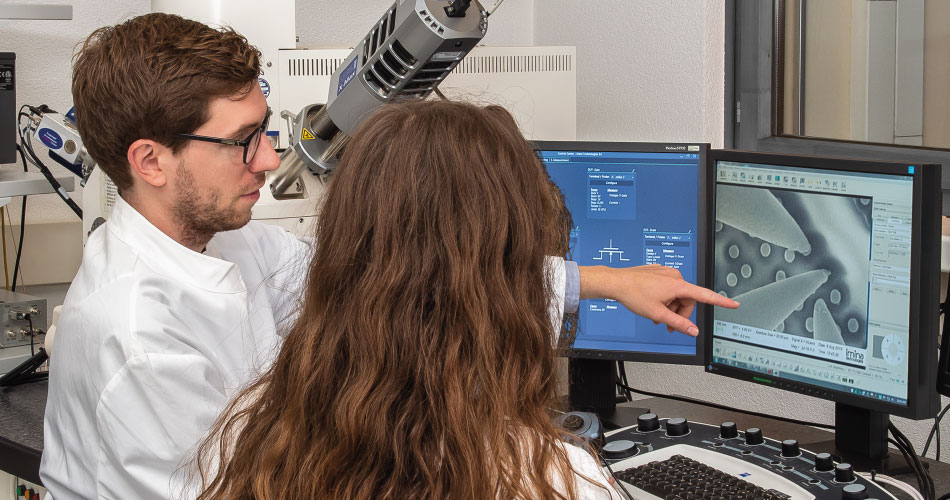

We have fully equipped demo lab for semiconductor electrical failure analysis. Our applications team is eager to perform live demonstrations and feasibility studies for you, onsite or online.

In the meantime, do not miss the opportunity to learn more about our products and applications with one of our webinars!